BYD Company Limited: Successful Rubber and Plastic Project Case Studies

In 2018, we learned from customer recommendations that Shenzhen Baolong BYD Factory had a demand for a rubber and plastic project. Our sales team acted quickly and took the initiative to contact BYD to express our strong interest and professional capabilities in the project.

1. Project contact

In 2018, we learned through customer recommendations that Shenzhen Baolong BYD Factory had a demand for a rubber and plastic project. Our sales team acted quickly and took the initiative to contact BYD, expressing our strong interest and professional capabilities in the project.

2. Inquiry

After the initial contact, BYD sent us a request for quotation. Our professional team immediately conducted a detailed analysis and evaluation of the project, including the type, quantity, and quality requirements of the required rubber and plastic materials, as well as factors such as the difficulty and duration of the construction. Based on these evaluation results, we developed a detailed quotation plan and responded to BYD in a timely manner.

3. Communication

Demand confirmation: After receiving our quotation, we had in-depth communication and further clarified the specific needs of the project. We listened carefully to the opinions and suggestions of customers, adjusted and optimized the quotation plan, and ensured that our plan could meet the needs of customers to the greatest extent.

Technical exchange: In order to enable customers to better understand our products and construction technology, we organized several technical exchange meetings. At the meeting, we showed customers the performance and advantages of our rubber and plastic products, as well as our successful experience in similar projects. At the same time, we also listened carefully to the customer's requirements for products and construction technology and made full preparations for subsequent negotiations and construction.

4. Negotiation

Price negotiation: After many rounds of communication and consultation, we reached an agreement with BYD on the price of the project. During the negotiation process, we fully considered the customer's budget and needs and also adhered to our principle of reasonable profit, and finally reached a price that both parties were satisfied with.

Contract terms negotiation: On the basis of price negotiation, we conducted in-depth negotiations on the contract terms. We carefully studied the contract template provided by the customer and analyzed and discussed the terms one by one. During the negotiation process, we fully considered the interests and risks of both parties and made reasonable adjustments and improvements to the contract terms to ensure the fairness and operability of the contract.

5 Signing the contract

After many rounds of communication, negotiation, and modification, we finally signed a formal contract with BYD. The contract clarifies the rights and obligations of both parties, including important terms such as the scope, construction period, quality standards, price, and payment method of the project. After signing the contract, we immediately set up a project team and began to prepare for the implementation of the project.

6. Material production and delivery

1. Production

Raw material preparation

Raw material preparation

Rubber raw materials: natural rubber, synthetic rubber, etc. Natural rubber mainly comes from the latex of rubber trees and has good elasticity and wear resistance. Synthetic rubber is prepared by chemical synthesis methods and has a wide variety of types, which can be selected according to different performance requirements.

Plastic raw materials: polyethylene, polypropylene, polyvinyl chloride, etc. These plastic raw materials have different properties, such as polyethylene having good corrosion resistance and insulation, and polypropylene having high strength and heat resistance.

Additives: In order to improve the performance of rubber and plastic products, various additives need to be added, such as stabilizers, lubricants, flame retardants, colorants, etc.

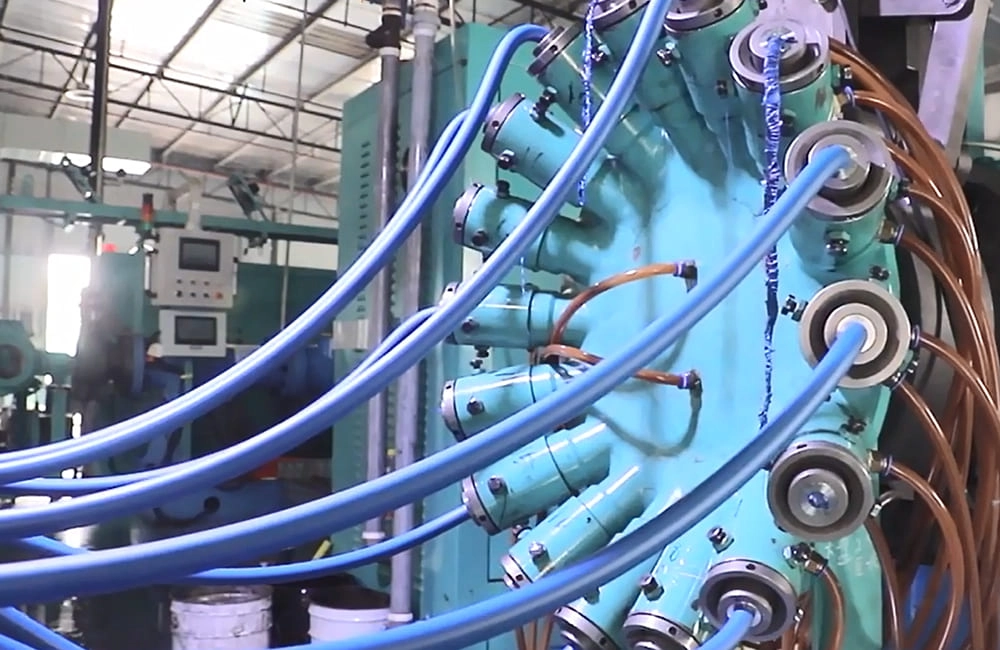

Production process

Extrusion

Molding: Molding the rubber compound into the desired shape by calendering, extrusion, molding, etc.

Vulcanization: Vulcanize the molded rubber product to make the rubber molecules cross-linked and improve the strength, elasticity and wear resistance of the product.

Plastic product production process:

Extrusion molding: After the plastic raw material is heated and melted, it is extruded into profiles of various shapes, such as pipes, plates, rods, etc. through an extruder.

Injection molding: Inject the molten plastic raw material into the mold and obtain plastic products of various shapes after cooling and solidification.

Blow molding: After the plastic raw material is heated and melted, it is blown into hollow products of various shapes, such as bottles, cans, etc., through a blow molding machine.

Quality control

Raw material inspection: strictly inspect the raw materials to ensure that they meet quality standards.

Production process control: monitor each link in the production process to ensure that the process parameters are stable and the product quality meets the requirements.

Finished product inspection: conduct a comprehensive inspection of the finished product, including appearance, size, performance, etc., to ensure that the product is qualified before leaving the factory.

2. Delivery

Packaging

Rubber product packaging: generally plastic bags, woven bags, cartons and other packaging methods are used. Choose the appropriate packaging material according to the shape and size of the product. For some special rubber products, such as seals, hoses, etc., special packaging is also required to prevent damage during transportation.

Transportation

Transportation method: The main transportation methods for rubber and plastic products are road transportation, railway transportation, water transportation and air transportation. When choosing a transportation method, factors such as the quantity, weight, volume, transportation distance and transportation time of the products need to be considered.

Transportation precautions: During transportation, care should be taken to prevent the products from being damaged by extrusion, collision, rain, sun exposure, etc. For some special rubber and plastic products, such as flammable, explosive, toxic and other products, they also need to be transported in accordance with relevant transportation regulations.

Shipping process

7. Construction

Construction preparation: At the same time as the materials were shipped, our project team also started construction preparation. We organized technical training and safety briefings for the construction personnel to ensure that the construction personnel were familiar with the construction process and safe operating procedures. At the same time, we also cleaned and organized the construction site to create good conditions for construction.

Construction process: During the construction process, we strictly carried out construction in accordance with the construction plan and quality standards. We strengthened the supervision and management of the construction process and promptly resolved problems that occurred during construction. At the same time, we also maintained close communication with BYD, and reported the construction progress and quality in a timely manner to ensure that the project could proceed smoothly.

8. Acceptance

Internal acceptance: After the construction was completed, we first conducted an internal acceptance. We organized professional technicians to conduct a comprehensive inspection and test of the project to ensure that the project meets the quality standards and contract requirements.

Customer acceptance: After the internal acceptance was qualified, we invited BYD to conduct customer acceptance. We submitted the acceptance report and relevant materials to the customer, and the customer conducted a field inspection and test of the project. After strict acceptance, the customer was very satisfied with the quality and effect of the project and passed the acceptance smoothly.

9. Project completion

After the customer acceptance was qualified, we went through the project completion procedures with BYD. We submitted the project completion report and relevant materials to the customer, and the customer gave a high evaluation of our work. At the same time, we also summarized and reflected on the project, providing valuable experience for future projects.

Through the cooperation of the Shenzhen Baolong BYD factory rubber and plastic project, we not only provided customers with high-quality products and services but also demonstrated our professional capabilities and team spirit. We believe that in future cooperation, we will continue to play our advantages and provide customers with better products and services.

Black Rubber-plastic Tube Rubber foam pipe wholesale

Special adhesive for insulation nail

This product has passed the EU REACH non-toxic standard and ROHS non-toxic standard. (This product is a yellow liquid).

Anggu insulation nail special adhesive is a adhesive with high viscosity, slow drying, aging resistance, high strength, and excellent brushing performance; The special adhesive for insulation nails has a slow drying speed and strong adhesion to the iron sheet. It can be flexibly moved during construction, and has a strong bonding force after curing, low odor.and is non-toxic.

Wholesale Glass Wool Board Panel Sheet with or without aluminum foil

Premium glass wool board with excellent thermal insulation and sound absorption. Suitable for different construction needs.

Foam Phenolic Adhesive

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. (The product is a yellow liquid.)

Anggu foam phenolic glue is a kind of glue with corrosion resistance, low odor, high strength and excellent brushing property. Can be sprayed for construction with fast surface drying speed, long bonding time, no chalking and convenient operation.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.