solution of wholesale insulation materials

Discover the key raw materials used in the production of high-performance rubber foam insulation. From elastomers to various additives, each component is selected by our insulation material company to ensure optimal insulation, durability, and flexibility.

Materials used in the production of foam insulation

Rubber compounds

NR

Provides flexibility and elasticity. Often used for its excellent vibration mitigation properties.

SBR, NBR, EPDM

Synthetic options offer specific benefits, such as better oil resistance (NBR) or improved weathering resistance (EPDM).

PVC

Polyvinyl chloride plastic is polymerized from vinyl chloride monomer and is one of the commonly used thermoplastics.

Foaming agents

Chemical foaming agents

Used to create the cell structure of the foam. Common foaming agents include azodicarbonamide (ADC) or citric acid.

Physical foaming agents

Include gases such as CO2 or nitrogen, which are introduced into the rubber mixture to form bubbles.

Cross-linking agents

Peroxides

Used to cross-link rubber molecules, enhancing the durability and thermal stability of the foam.

Sulfur

Another cross-linking agent that improves the strength and elasticity of rubber.

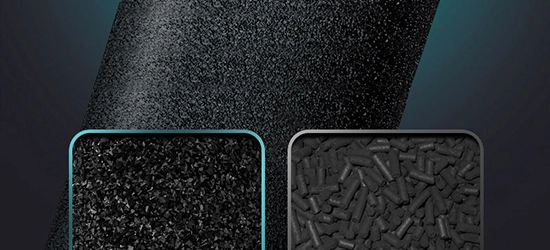

Fillers

Carbon black

Provides UV protection and enhances the mechanical strength of the foam.

Silicone

Used to improve processing properties and reduce the tendency of the foam to collapse.

Additives

Flame retardants

Essential for improving the fire resistance of the foam. Examples include brominated compounds or phosphate esters.

Antioxidants

Prevent rubber materials from degrading due to oxidation, extending the service life of the insulation material.

Colorants

Pigments and dyes

Added to achieve specific colors, for aesthetic optical purposes or to meet customer requirements.

Adhesives

Contact adhesives

Used to bond the foam to other materials or surfaces.

Pressure sensitive adhesives

Used where easy application and removal is required.

Surface coatings

Protective coatings

Applied to enhance resistance to environmental factors such as UV or moisture.

Decorative coatings

Used to achieve specific surface effects or textures.

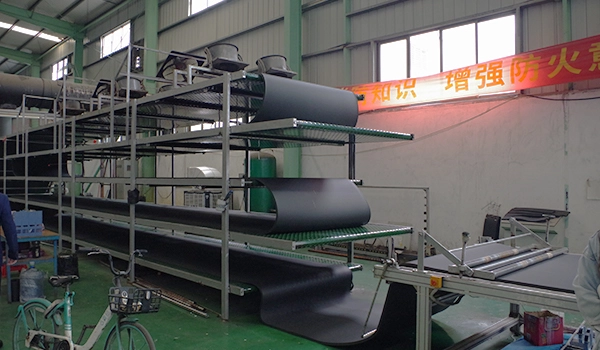

Processing equipment

Extruders

Used to shape the foam material into the desired contours.

Moulding equipment

For producing custom shapes and sizes.

Curing ovens

Ensure proper cross-linking and stabilization of the foam material.

Production Process

our rubber and plastic insulation products

FUNAS main rubber and plastic insulation products, rock wool products, and glass wool products.

Our products are widely used in petroleum and petrochemical, electric power, metallurgy, polysilicon, coal chemical industry, central air conditioning, refrigerator refrigeration, and other fields.

Learn More

Closed-Cell Rubber Foam

Closed-Cell Rubber Foam is an insulation material characterized by a compact, non-porous structure. Each cell in the foam is closed, which prevents moisture penetration and enhances thermal insulation properties.

Applications

Suitable for HVAC systems, refrigeration and pipe insulation.

High moisture resistance, excellent thermal insulation and durability. It is also flexible and can conform to a variety of shapes.

Neoprene Rubber

Material Description: Neoprene, also known as polychloroprene, is a synthetic rubber with high chemical resistance and flexibility. It is often used in applications that require resistance to heat, ozone and aging.

Advantages

Good resistance to oils and chemicals, excellent weather and UV resistance.

Advantages

Used in automotive gaskets, seals and insulation materials in extreme temperature environments.

EPDM (Ethylene Propylene Diene Monomer)

EPDM is a synthetic rubber known for its excellent weather resistance and resistance to heat, ozone and aging. It is often used in outdoor applications.

Application

Commonly used in roof membranes, automotive seals, and insulation of outdoor pipes and equipment.

Advantages

Excellent resistance to environmental factors and good flexibility at low temperatures.

Polyethylene Foam

Polyethylene foam is a lightweight, flexible material with a closed-cell structure that is a popular choice in various insulation applications. It provides good thermal insulation and cushioning properties.

Applications

Used for packaging, construction, and insulation of pipes and tanks.

Advantages

Good thermal insulation, moisture resistance, and easy handling.

Polyurethane Foam

Polyurethane foam is a versatile material used in a variety of applications, including insulation. It can be made into flexible or rigid foams depending on specific needs.

Applications

Used for building insulation, refrigeration insulation, and cushioning materials in various products.

Advantages

Excellent thermal insulation, lightweight, and customizable density.

Silicone Rubber

Silicone rubber is a high-performance material known for its heat resistance, flexibility, and durability. It can withstand extreme temperatures and harsh environmental conditions.

Applications

Used for high-temperature seals, gaskets, and insulation in industrial applications.

Advantages

High heat resistance, chemical stability, and long-term durability.

Glass Fiber Reinforced Foam

This material combines foam with glass fibers to enhance its mechanical properties and thermal insulation. Glass fibers provide additional strength and rigidity.

Applications

Used in applications that require enhanced mechanical strength and thermal insulation, such as aerospace and automotive industries.

Advantages

Improved structural strength, excellent thermal insulation, and impact resistance.

Melamine Foam

Melamine Foam is an open cell foam known for its acoustic properties and flame retardancy. It is commonly used in sound insulation and fire protection applications.

Applications

Commonly used in acoustic sound absorbing panels, acoustic treatments, and insulation materials in fire protection applications.

Advantages

Excellent sound absorption, flame retardancy, and low thermal conductivity.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.